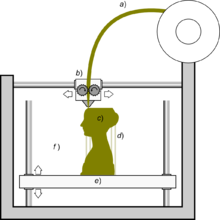

Additive manufacturing of food is being developed by squeezing out food, layer by layer, into three-dimensional objects. A large variety of foods are appropriate candidates, such as chocolate and candy, and flat foods such as crackers, pasta,[115] and pizza.[116][117] NASA is looking into the technology in order to create 3D printed food to limit food waste and to make food that is designed to fit an astronaut's dietary needs.[118] In 2018, Italian bioengineer Giuseppe Scionti developed a technology allowing the production of fibrous plant-based meat analogues using a custom 3D bioprinter, mimicking meat texture and nutritional values.[119][120]

Fashion industry

3D printing has entered the world of clothing, with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses.[121] In commercial production, Nike used 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance has 3D manufactured custom-fit shoes for athletes.[121][122] 3D printing has come to the point where companies are printing consumer grade eyewear with on-demand custom fit and styling (although they cannot print the lenses). On-demand customization of glasses is possible with rapid prototyping.[123]

Vanessa Friedman, fashion director and chief fashion critic at The New York Times, says 3D printing will have a significant value for fashion companies down the road, especially if it transforms into a print-it-yourself tool for shoppers. "There's real sense that this is not going to happen anytime soon," she says, "but it will happen, and it will create dramatic change in how we think both about intellectual property and how things are in the supply chain". She adds: "Certainly some of the fabrications that brands can use will be dramatically changed by technology."[124]