There are many different branded additive manufacturing processes, that can be grouped into seven categories:[80]

- Vat photopolymerization

- Material jetting

- Binder jetting

- Powder bed fusion

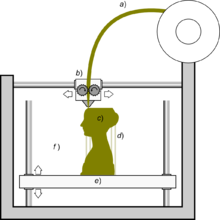

- Material extrusion

- Directed energy deposition

- Sheet lamination

The main differences between processes are in the way layers are deposited to create parts and in the materials that are used. Each method has its own advantages and drawbacks, which is why some companies offer a choice of powder and polymer for the material used to build the object.[81] Others sometimes use standard, off-the-shelf business paper as the build material to produce a durable prototype. The main considerations in choosing a machine are generally speed, costs of the 3D printer, of the printed prototype, choice and cost of the materials, and color capabilities.[82] Printers that work directly with metals are generally expensive. However less expensive printers can be used to make a mold, which is then used to make metal parts.[83]

ISO/ASTM52900-15 defines seven categories of additive manufacturing (AM) processes within its meaning: binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photopolymerization.[84]

The first process where three-dimensional material is deposited to form an object was done with material jetting[25] or as it was originally called particle deposition. Particle deposition by inkjet first started with continuous inkjet technology (CIT) (1950s) and later with drop-on-demand inkjet technology (1970s) using hot-melt inks. Wax inks were the first three-dimensional materials jetted and later low temperature alloy metal was jetted with CIT. Wax and thermoplastic hot-melts were jetted next by DOD. Objects were very small and started with text characters and numerals for signage. An object must have form and can be handled. Wax characters tumbled off paper documents and inspired a liquid metal recorder patent to make metal characters for signage in 1971. Thermoplastic color inks (CMYK) printed with layers of each color to form the first digitally formed layered objects in 1984. The idea of investment casting with Solid-Ink jetted images or patterns in 1984 led to the first patent to form articles from particle deposition in 1989, issued in 1992.

No comments:

Post a Comment